Filleting is a crucial step in 3D design, especially for professionals in consumer product design and industrial design. However, achieving a smooth, well-defined fillet can be challenging, even for experienced users.

In this guide, we’ll explore how to use the fillet tool in SOLIDWORKS effectively, share fillet techniques to enhance your designs, and provide solutions for fixing fillet errors in SOLIDWORKS.

Key Features of SOLIDWORKS' Fillet Tool

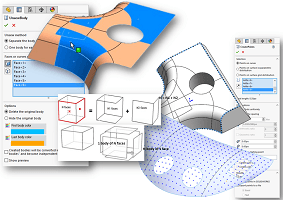

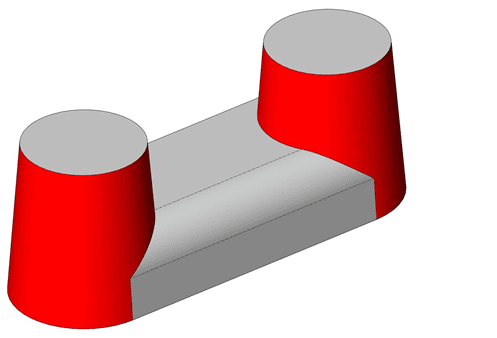

One thing that you might be interested to know is that ‘filleting’ always needs to find somewhere to end, as seen in the example below:

The SOLIDWORKS fillet tool can automatically extend the selected (red) faces of a part, creating a defined area where the fillet can terminate. This ensures that the fillet has a clear starting and ending point, streamlining the process and improving efficiency.

Types of Fillets in SOLIDWORKS:

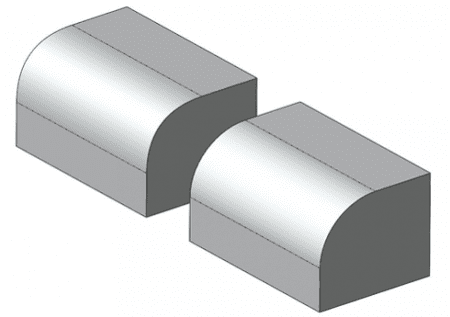

1. Constant Size Fillet

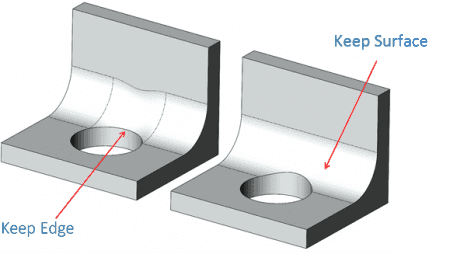

2. Constant Size Fillet- Keep Edge/Keep Surface

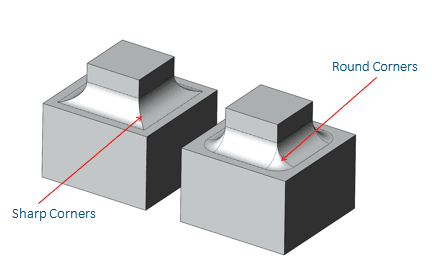

3. Constant Size Fillet- Round Corners

4. Conic Fillets

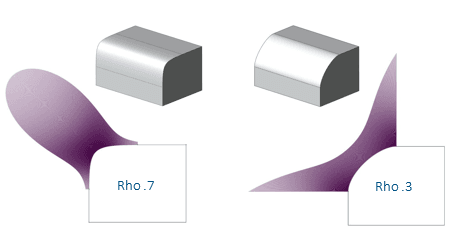

The Conic Fillet tool creates fillets with a shape based on parts of a hyperbola. The appearance of the fillet changes depending on the input values. Values closer to 1 create sharper fillets, while values closer to 0 create flatter ones. As a general guideline, use values greater than 0.5 for best results.

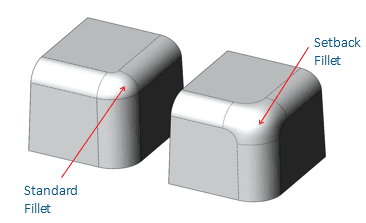

5. Setback Fillets

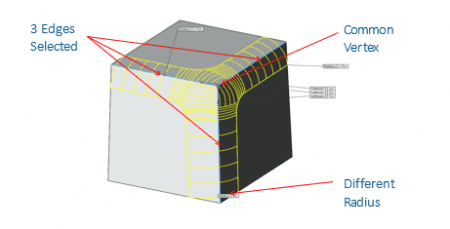

Setback Fillets offer additional options for corner treatments. Setback fillets create softer corners where 3 fillets meet a common vertex. All three common edges must be filleted in the same feature. Enable Multiple Radius Fillet for different sizes. Select the common vertex under Setback Parameters. Select a size and hit Set All.

6. Variable Size Fillet

Variable Size Fillets alter their dimensions along the length based on user-defined settings and also accommodate Conic Fillets.

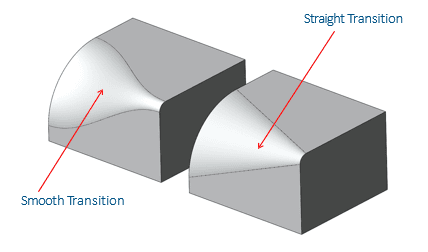

7. Variable Size Fillet- Smooth/Straight Transitions

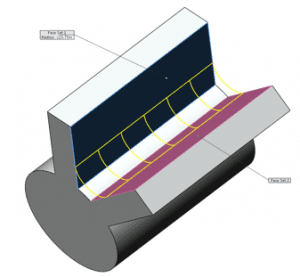

8. Face Fillet

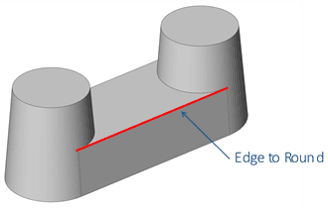

Face fillets can create the same types of fillets as the Constant size command. Their power lies in their ability to select faces to define a fillet, instead of an edge between two faces.

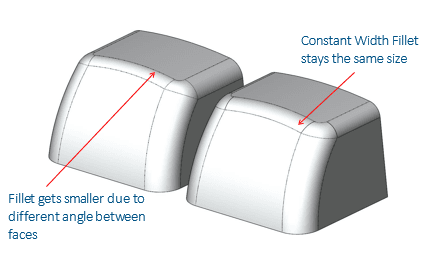

9. Constant Width Face Fillet

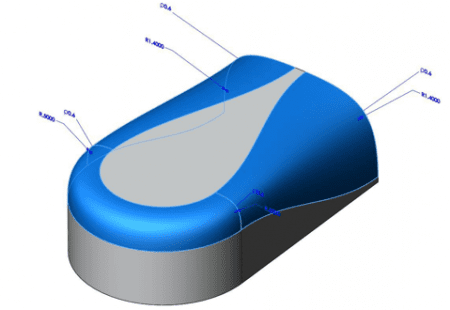

Constant Width Face Fillets maintain a consistent appearance along their length, yet the radius value varies across the length.

10. Full Round Fillets

Full round fillets are useful for rounding off geometry. They will change in radius along their length to ensure the fillet is tangent to three adjacent faces.

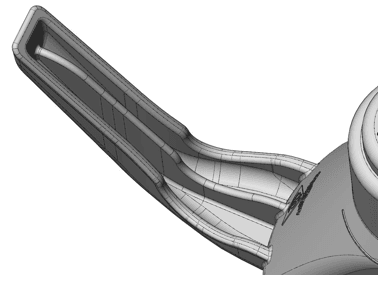

Handling Tricky Fillets

It is common for errors throughout the process. These are the 2 most common reasons that a fillet may fail:

1. The software is unable to extend one or more faces along the path of the fillet giving somewhere for the fillet to end.

2. The fillet is too large for the geometry. It might only be in one small portion of the fillet path, but it will still cause the feature to fail.

Example:

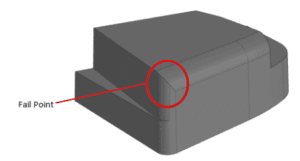

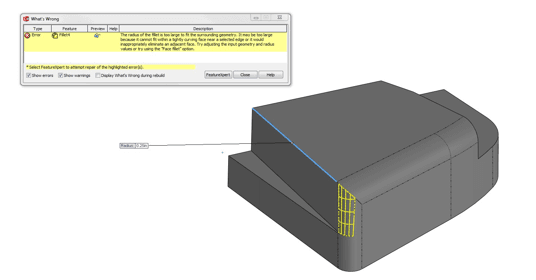

This component requires a 25° fillet along the highlighted edge. Due to an error, SOLIDWORKS is unable to add a fillet to the desired radius.

3 Simple Steps to Solve Filleting Failures

Step 1 – Identify Fail Points

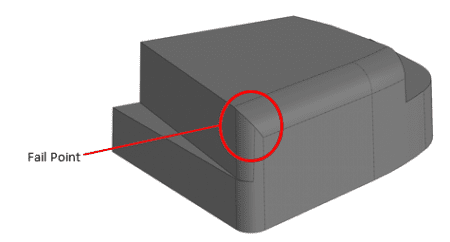

The fillet is most likely failing at the corner because SOLIDWORKS is unable to extend the corner faces to terminate the fillet.

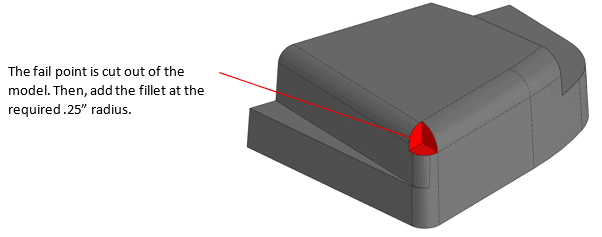

Step 2 – Cut Away the Fail Point

Add the fillet at required 25° radius after fail point is cut out of the model.

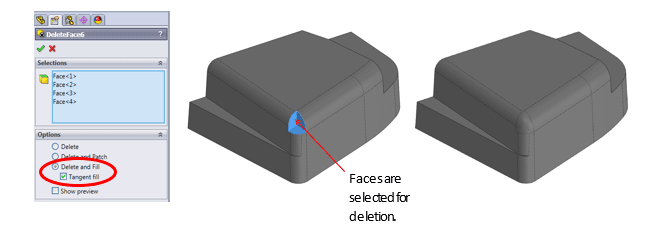

Step 3 – Repair the Corner

Use delete face and fill to close the corner.

You may reach out to [email protected] for technical assistance or browse SOLIDWORKS Help for more information.

If you found this blog post helpful, we’d love for you to share it!