Ever wondered why your smartphone survives multiple drops yet cracks from a minor slip? Smartphone durability has become a critical feature, with manufacturers striving to find the perfect balance between sleek aesthetics, lightweight design, and resilience. Beneath the smooth surface of your phone lies advanced engineering, powered by SOLIDWORKS Simulation, that ensures it can withstand the rough-and-tumble of daily life.

Materials and Design Choices

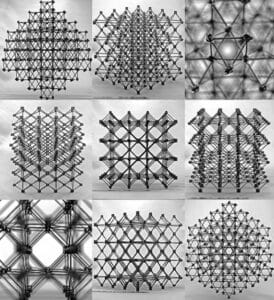

Smartphone durability starts with material selection—typically a mix of metals, glass, and polymers. Each material contributes to strength, flexibility, and aesthetics. However, manufacturers must balance durability with weight and cost. Lighter materials enhance portability but may sacrifice strength, while tougher materials add weight. The challenge is optimizing lifespan and usability without compromising design and performance.

How SOLIDWORKS Simulation Ensures Durability

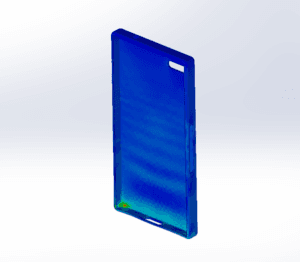

Before your smartphone even hits the market, it undergoes extensive virtual testing using advanced tools like Simulation. These simulations help engineers predict how a device will react to various forces, such as drops, pressure, and impact.

By simulating real-world scenarios, manufacturers can analyze the phone’s structural integrity without excessive physical testing, ensuring a more cost-effective and efficient design process.

The Role of Simulation

To predict durability without excessive physical testing, engineers rely on simulations. These include:

Structural Analysis: Determines how forces impact components under normal conditions.

Drop Tests: Simulates falls from various heights and angles to assess shock absorption and weak points.

Impact Forces: Measures the force exerted during impact to identify vulnerable areas.

Real-World Benefits of SOLIDWORKS Simulation

For Manufacturer:

- Reduces costs and time spent on physical testing.

- Speeds up the production of more durable smartphones.

- Improves quality assurance and warranty reliability.

For Consumer:

- More resilient smartphones that better withstand drops and pressure.

- Enhanced durability without compromising lightweight design.

Key Insights from SOLIDWORKS Simulation

Impact Thresholds

Defines the point at which damage occurs.

Failure Modes

Simulations allow engineers to pinpoint these failure modes.

Design Insights

Provides actionable insights to enhance durability before manufacturing prototypes.

Beyond Drops: The Bigger Picture of Product Durability

While drop tests are critical, smartphones face more than just accidental falls. Vibrations, repeated stress, and unexpected shocks can also lead to failure over time. This is where advanced shock and vibration simulations help ensure long-term durability.

However, drop tests are only one part of the equation. In reality, smartphones—and many other products—face more than just accidental falls. Vibrations, repeated stress, and unexpected shocks over time can also lead to failure. This is where advanced shock and vibration simulations come into play.

Curious about how products endure real-world conditions beyond drops? Learn more in our next blog: Drop Tests Only Tell Half the Story – SOLIDWORKS Simulation Reveals the Rest.

Want to see how cutting-edge simulations can enhance product durability? Discover how SOLIDWORKS Simulation helps engineers design tougher, more reliable devices. Contact us today for expert guidance or explore SOLIDWORKS Simulation to revolutionize your product development!