XYZ range finder, character handling, line numbering, renumbering, tool compensation, fundamental math operations, and more are all included in this extensive editing toolkit.

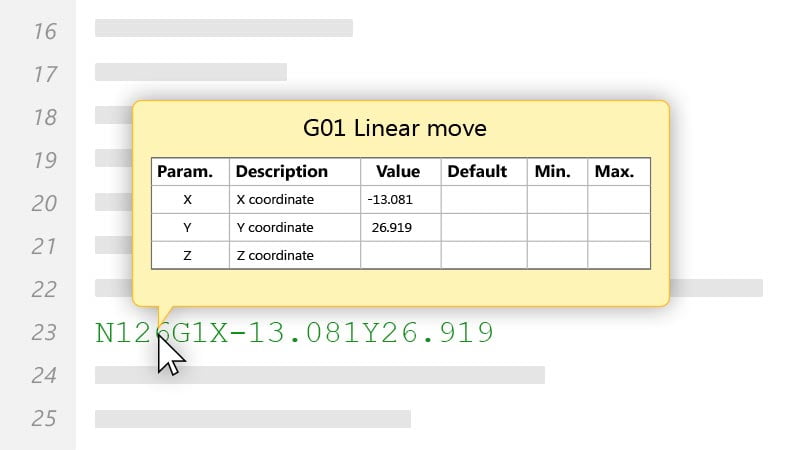

The NC-Assistant will recognize any M or G code that you point to, identify it, and let you change its values via an interactive interface that is connected to the CNC code. The code will automatically change as you enter the desired values.

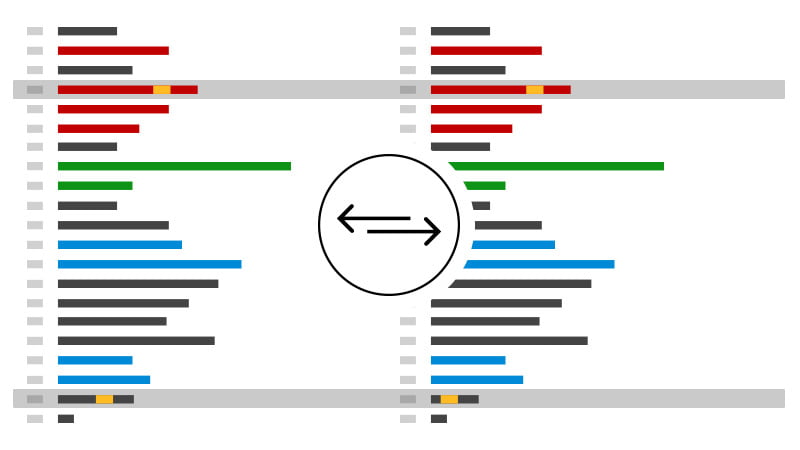

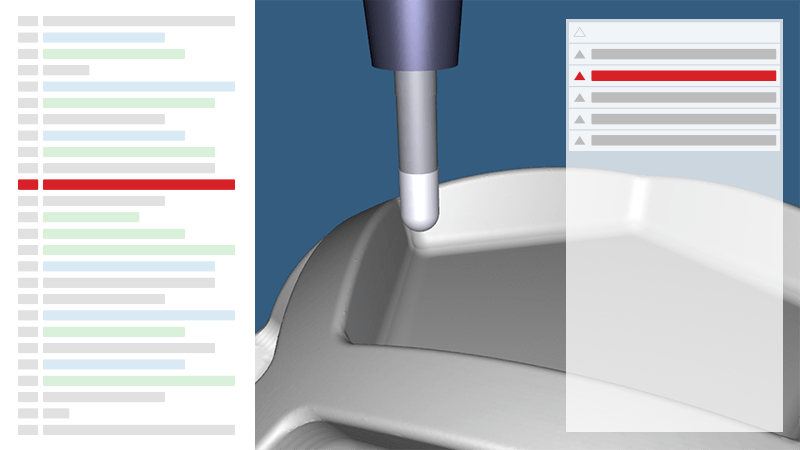

While minor format adjustments like block renumbering and spacing are ignored, the file comparison detects newly added, altered, and removed lines. One line at a time, all at once, or printed side by side for offline examination are the available presentation options for differences.

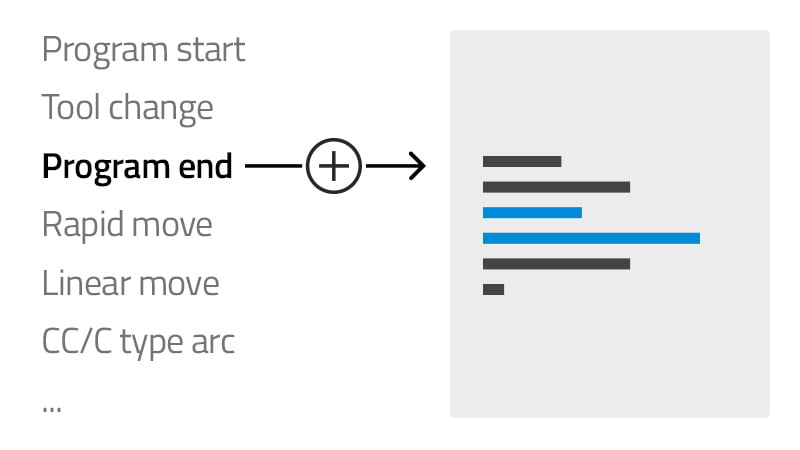

For the procedures that are most typical to your setup, you may record your own or quickly insert and edit cycles and operations. has built-in cycles and macros for changing tools, stopping programs, and many other things.

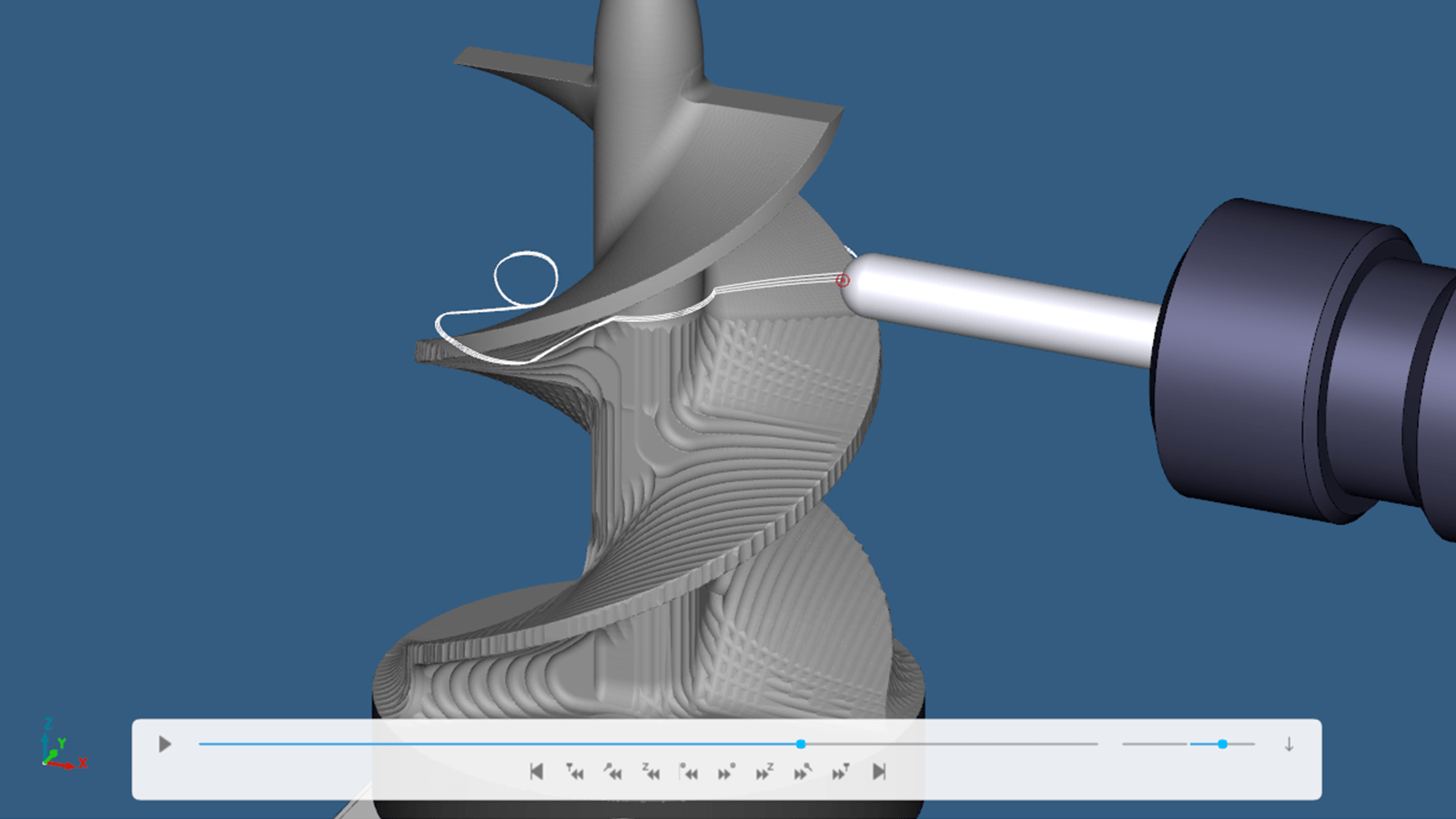

The mill-turn C+Y axis backplotter, turning, and 3,4,5 axis milling allows you to simulate your NC programs in three dimensions. High-quality, GPU-accelerated simulation of gouge detection, stock material removal, and other tasks.

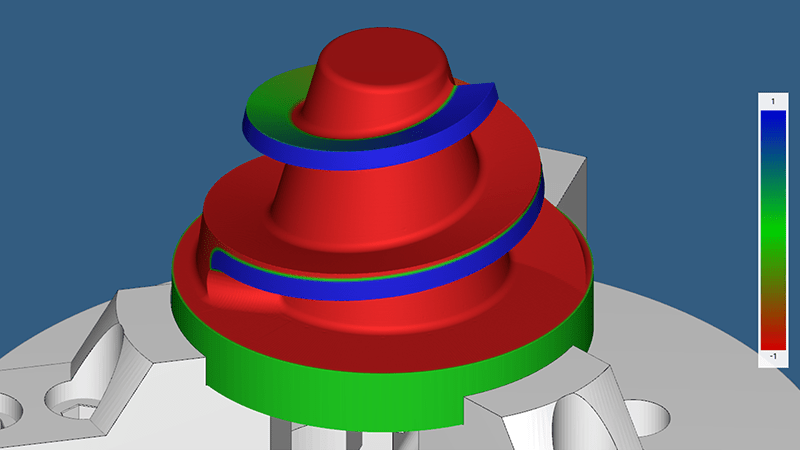

To quickly spot errors, compare the simulated stock to the design model. The color of the stock is determined by how far it is from the design model.

The Simulation Report displays all of the software faults. Click on an error to get to the line that corresponds to it. If you make changes to the code, the Simulation Report will confirm that the issue has been fixed.

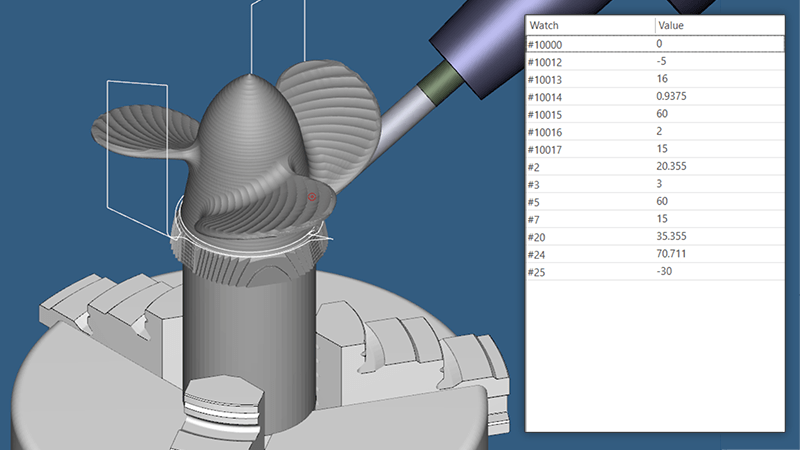

While the simulation is running or when you are choosing individual lines, keep track of the beginning and current states of the variables in your NC program. Additionally supported are machine state variables.

An excellent start to CIMCO Edit. You may learn trigonometry, NC coding, milling and turning, and much more via our online training classes.

UltiMaker Cura 3D lets users customize the software by adding plugins, which can integrate other tools, handle special file formats, and add new features. This flexibility allows users to adapt the software to their needs, improving their 3D printing workflow. Plugin development is open to everyone, giving users the freedom to extend Cura’s core capabilities.

Discover SOLIDWORKS Ultimate: the all-in-one platform that integrates 3D design, simulation, manufacturing, marketing, and management tools. Streamline collaboration and accelerate innovation today

Efficiently create complex steel structures with SolidSteel Parametric. This tool enables quick generation of intricate connection types with just a few clicks, automatically adjusting all connected beams as needed. It conforms to industry standards, ensuring fast and accurate construction processes.

Even the most innovative ideas fail if they can't be manufactured efficiently. Revolutionize your CNC operations with SolidCAM's exclusive and patented iMachining technology - all directly inside SOLIDWORKS.

DriveWorks enables businesses to streamline operations with personalized design automation and 3D sales configuration systems. Empower teams and customers to design, engineer, and customize orders effortlessly across all devices, reducing errors and accelerating product delivery.

Unleash the full potential of CNC program editing with CIMCO Edit. From NC-specific functions to drag-and-drop editing, experience precision with file compare, mill/turn backplotter, advanced Tool Manager, NC code assistant, and a suite of powerful add-ons for machine simulation, program management, 2D CAD/CAM, and beyond.

The leading CAD/CAM solution for woodworking and furniture design. Seamlessly integrated with SOLIDWORKS, SWOOD offers innovative tools to streamline your creative process and enhance efficiency.

The expertise and insight to keep things on track and deliver results, beginning with closing the performance gap in manufacturing operations.

Utilise production planning and manufacturing scheduling software to consistently meet customer demands.

Simple Programming for Complex Multiple Turret and Spindle Swiss-type CNC Machines.

The Most Powerful and Easiest Definition of Coordinate Systems for Indexial 5-Axes.

3D Machining wiht Powerful Roughing & Finishing Tool Paths.

SolidCAM's High Speed Surface Machining of Localized Surfaces.

Produce quality inspection documentation by eliminating input errors, reduce time to market and better quality.

Gain unprecedented visibility and control over your manufacturing shop floor with production data

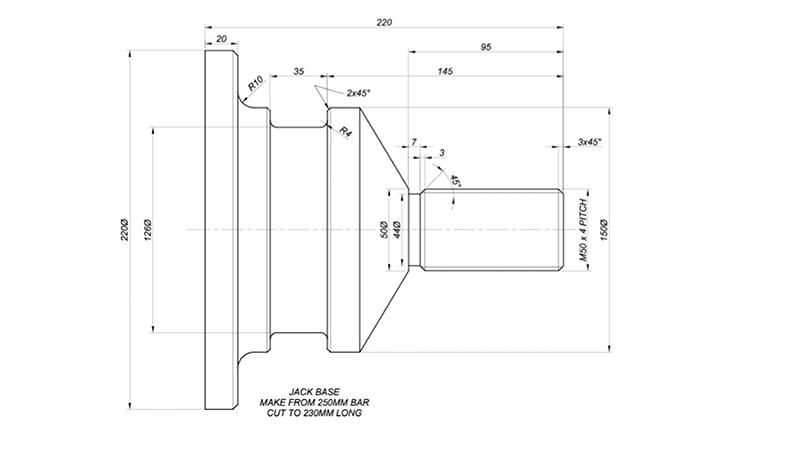

Easily create instructions for CNC machines to manufacture parts quickly without delays or errors.

The Most Powerful & Easiest Way to create 2.5D CNC Milling Toolpaths

Powered by the 3DEXPERIENCE platform, DELMIA connects virtual and real worlds of value networks to address challenging situations manufacturers experience today.

DELMIAWorks is a shop-floor-first, end-to-end Enterprise Resource Planning (ERP) system that helps mid-market manufacturs improve plant floor by increasing efficiency and visibility of the performance.

Achieve operational excellence and bridge the gap between design and manufacturing with optimized manufacturing, production, and execution processes

"*" indicates required fields

Professional software trainings for your employees

Professional Examination CSWP for free per serial number

24/7 Online access to vital information and resources

By experienced application engineers

Upgrades software and service pack automatically

Experience the power of advanced technology and gain a competitive edge in the market. Request a demo today or contact us to get started on your journey towards success!