In shopfitting, you need precision, speed and the ability to handle constant change in customer demands. SWOOD, working inside SOLIDWORKS, helps you manage the entire process, from design through to production. With parametric tools, smart material handling and accurate layouts, it becomes easier to cover a wide product range without losing control of details.

Because SWOOD is dedicated to woodworking, you can design custom furniture and fittings, then manufacture them at scale using the same parametric rules.

Below are 5 ways SWOOD can support your shopfitting projects.

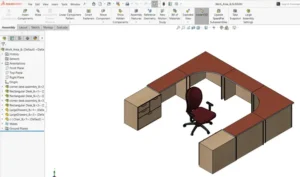

1. Modify complete shopfitting layouts in one step

SWOOD lets you build full rooms in layout mode, such as kitchens, retail spaces, wardrobes and more, using your own frame templates. Once you have placed your cabinets and fittings, you can respond to customer requests quickly by adjusting dimensions for all the furniture elements in the assembly at once.

This means you can rework sizes and proportions without redrawing everything from scratch.

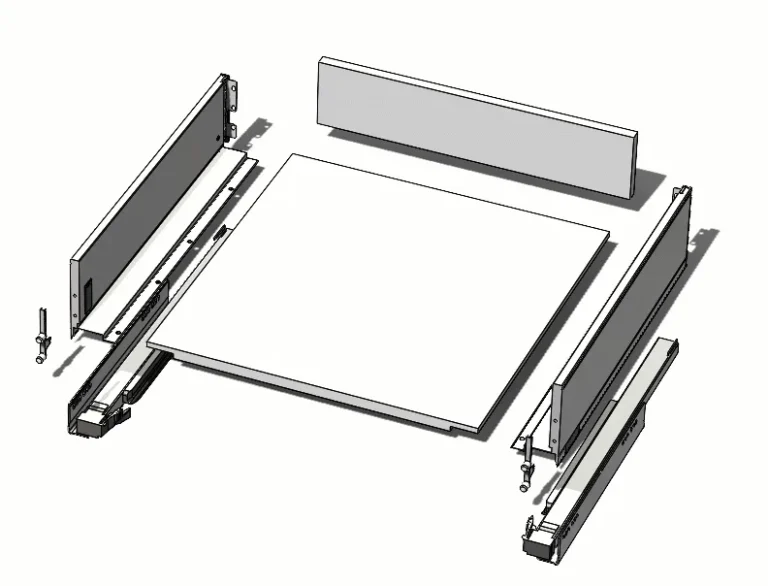

2. Design faster with intelligent library components

SWOOD includes a library system that lets you define rules and behaviour for your standard elements, such as connectors, SWOOD Boxes and other fittings. You can:

Configure how these components behave

Save your company know how inside the library

Maintain consistency from one project to another

Using drag and drop, you can place hardware such as drawers, hinges, shelves, dividers, cable grommets and similar items directly into your design. The intelligent components in your library bring their own machining operations with them, so the related drilling and routing is added automatically. This saves time and reduces the chance of manual input errors.

3. Produce and nest your shopfitting projects efficiently

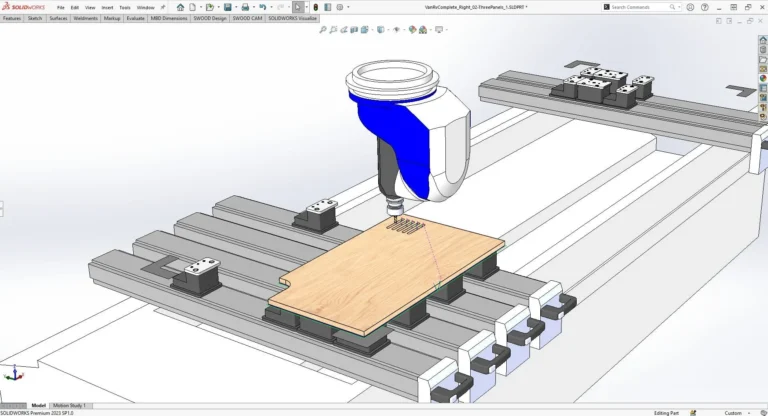

From a 3D design, SWOOD can generate CNC programs and workshop documents and then optimise production. The solution provides wood specific machining strategies and supports both point to point machining and nesting workflows.

SWOOD can detect 3 axis and 5 axis operations and create tool paths based on flexible strategies. When you change the design, the associated machining updates with a single click, so you do not have to reprogram everything by hand.

4. Control your workflow with strong CNC integration

SWOOD is designed to integrate with leading CNC brands used in woodworking and shopfitting, such as HOMAG, SCM, BIESSE and others.

By connecting design, CAM and machine programs, you gain better control over:

Pre production simulations

The order of operations

The full production workflow

This level of integration helps increase manufacturing efficiency and reduces the risk of surprises on the shop floor.

5. Improve coordination and data exchange

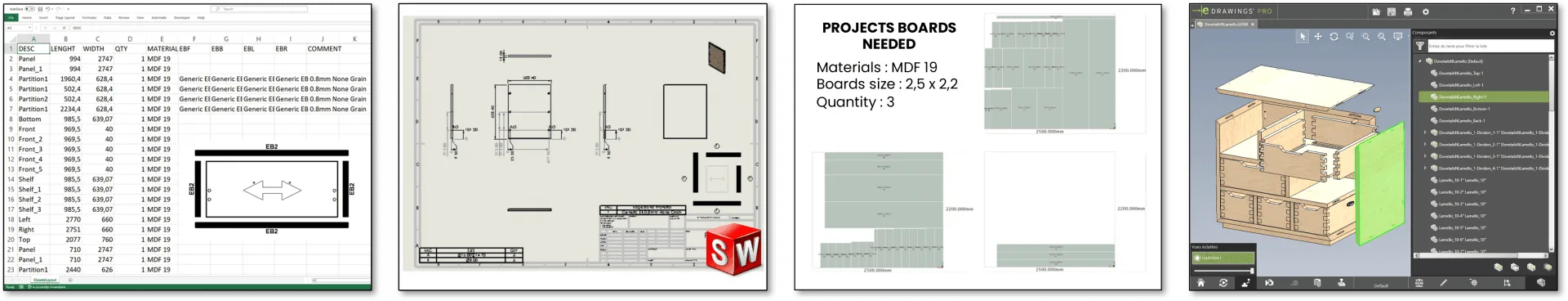

For each project, SWOOD automatically gathers the parameters of all design elements and produces a complete project report. This can include:

Material lists

Hardware requirements

Machining programs

Cutting lists and similar documents

You can export these reports in formats that match your workshop and office systems. When you change a parameter in the design, the linked programs and documents are updated and can be regenerated in one click. This keeps everyone working from the same information, from design to production.

By combining parametric design, intelligent libraries, nesting and CNC integration, SWOOD helps shopfitters manage projects more consistently and efficiently, from initial layout to final production.

Ready to Improve Your Design and Manufacturing Workflow

If you want to streamline your CAD and CAM processes and get more from your existing tools, our team at CADVision Systems is here to help. We support engineers and designers in Singapore and Malaysia with software, training and guidance tailored to real projects. Contact us today!

Adapted from SWOOD Blog: “5 ways SWOOD can help to elevate your shopfitting projects”.