When we exhibit our designs, there are times when we want to keep certain aspects of our designs private. The confidential information is essential to the products’ overall performance and design. SOLIDWORKS has therefore taken action to safeguard the valuable intellectual property of a product’s designer. The “Defeature tool” was introduced by SOLIDWORKS to assist designers in concealing specific attributes or details when presenting their designs to others.

You can use the Defeature tool to eliminate details from an assembly part and store the results in a new file with “solid” in place of the details. As a result, you can distribute the updated file without disclosing every aspect of the model’s design. This feature also helps to save the less-detailed model to separate file and maintain references to the original part or assembly as well as specifying the details to be removed when customers configure and download the model.

The defeature is not only for Part designs also helpful for handling large assembly files. Since, Large assembly files has more number of components [internally & externally], the rebuild time and large file size is more. Therefore, defeaturing also helps users to share the files effectively.

SOLIDWORKS Defeature Tool

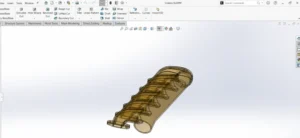

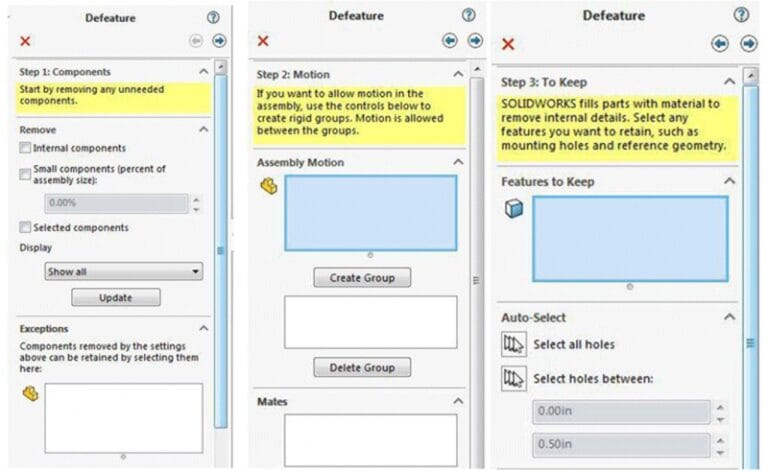

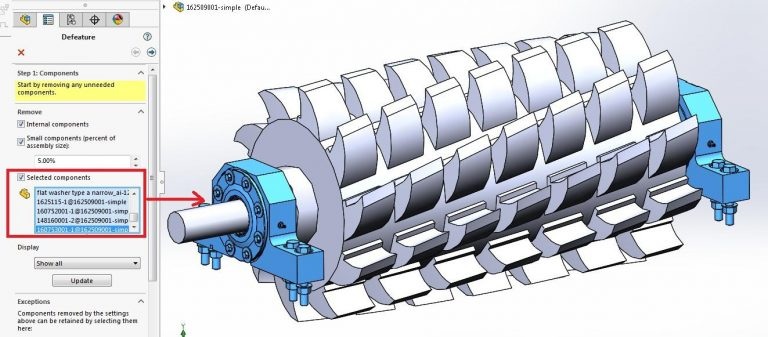

The above diagrams show the step 1 to step 3 in selecting the parts and components you wish hide from people. Removing components can be done by 2 methods. One is based on size and other is selective components. In the diagram shared, “selective components” option method is chosen. Hence, selective components and small components with 5% of assembly such as nuts, bolts, washer etc are removed.

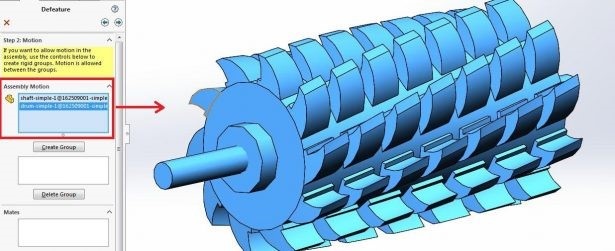

After selection of components, I moved to next step to control motions of my assembly. Hence, a group so that motion is allowed between the groups.

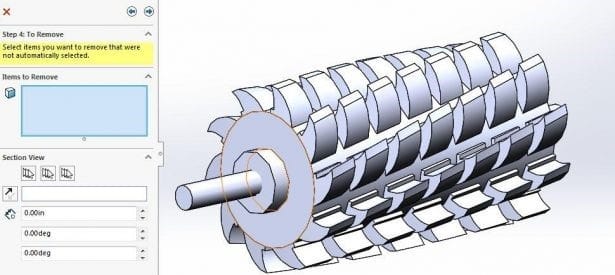

Next, we are going to step 2 which is the motion selection. In this scenario, no retain to any feature and geometry. Therefore, the box is left empty. We shall proceed to next step which is removing the features we like. Since, all the necessary parts already removed in step 1. Hence, the box is left to be blanked again.

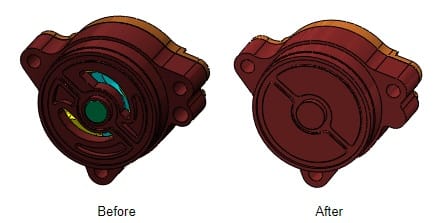

Hence, the final output will be as shown below. The amazing result with no extra feature is shown. Of course, the size of the assembly has been reduced and so do the size of the files. The rebuild time of the design in between “without defeature” and “with defeature” are different.

Before defeature, the size will be bigger as all the parts are squeezed inside a file. However, after defeaturing, the size of the file has been reduced hence shorter time is required to read and rebuild the contents.

If you encounter an issue to uninstall 3DEXPERIENCE Design, you may contact [email protected] for assistance.

If you found this helpful, we’d love for you to share it!