If you spend a lot of time drawing in DraftSight and want your corners to look more refined, you’ve probably seen the Chamfer tool sitting near the Fillet command in the ribbon. It’s easy to scroll past, but once you understand what it does, it becomes one of those tools you’ll reach for often.

Below, we’ll look at what a chamfer actually is, how it behaves in DraftSight, and why it’s worth including in your everyday drafting workflow.

What Is a Chamfer?

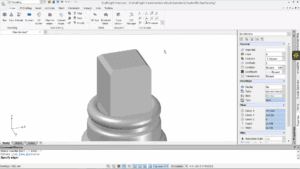

In simple terms, a chamfer is a straight, angled cut that replaces a sharp corner. Instead of two lines meeting at a point, a chamfer adds a short, beveled edge that connects them.

Where a fillet rounds off a corner with a curve, a chamfer keeps things linear and angular. The result is a clean, straight connector between two edges—no arcs, just a precise bevel.

In DraftSight, the purpose of a chamfer is to:

Soften or simplify sharp corners

Reduce stress concentrations at edges

Make the design intent clearer in both architectural and mechanical drawings

Chamfered corners help show where an edge shouldn’t be sharp or where parts are meant to fit or align.

Why Use Chamfered Edges in Your Drawings?

Chamfers show up frequently in professional designs for a few reasons:

They’re easy to read on technical drawings

They can improve function, especially where sharp corners are not desirable

They can help with manufacturing and printing, making edges easier to machine or produce

A chamfered corner can indicate:

A functional edge (for assembly or clearance)

A safety feature (removing sharp points)

A visual refinement for a more polished look

In short, chamfers help your drawing look better, behave better, and more clearly communicate the intent behind your design.

Chamfer vs. Fillet — What’s the Difference?

It’s easy to confuse fillets and chamfers since both modify corners, but they serve different purposes:

Feature | Chamber | Filet |

|---|---|---|

Shape | Straight angled edge | Rounded Edge |

Purpose | Structural precision, sharp definition | Smooth transitions, flow |

Typical Use | Mechanical parts, architectural edges | Ergonomic or fluid designs |

How to Create a Chamfer in DraftSight

Using the Chamfer tool in DraftSight is quite straightforward once you’ve tried it a few times.

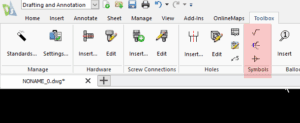

Start the Chamfer command

Select the Chamfer tool from the ribbon (it sits close to the Fillet command).

Choose how you want to define the chamfer

DraftSight gives you a couple of options:Distance: Set how far back from the corner each line should be cut.

Angle: Set one distance and an angle to control the chamfer shape.

Select the lines to chamfer

Click the first line.

Click the second line.

DraftSight will automatically place the beveled edge based on your chosen settings.

Decide what happens to the original lines

Just like with Fillet, you can control whether the original corner geometry is trimmed or left as-is, depending on how you want your final corner to look.

Best Practices for Chamfering in DraftSight

To get the most out of chamfers in your drawings, keep these habits in mind:

Be consistent

If you’re using chamfers across a drawing, try to keep distances or angles consistent unless there’s a specific functional reason to vary them. Small, uniform chamfers often give your designs a more professional feel.Check your units

Before you start chamfering, make sure your units are correct—especially when working with imported geometry. A mismatch between millimeters and inches (or other units) can make a chamfer look oversized or too small.Mixing chamfers and fillets with intention

It’s common to use fillets in some areas and chamfers in others on the same part or assembly. This can create a nice visual and functional contrast, as long as the choices are intentional and support the design’s purpose.

Adapted from DraftSight Blog: “What is a Chamfer in DraftSight? Everything You Need to Know”.