In a world where speed and efficiency define success, building physical prototypes for every product iteration is both costly and slow. That’s where virtual prototyping comes in—and it’s changing the game.

Instead of guessing, building, breaking, and rebuilding, engineers are now turning to SOLIDWORKS Simulation to test ideas virtually. It’s fast, smart, and gives your team confidence before a single screw is turned.

Virtual Prototyping: What It Really Means

Virtual prototyping is the process of simulating a product’s performance using digital models and computer-aided analysis—before it’s physically built.

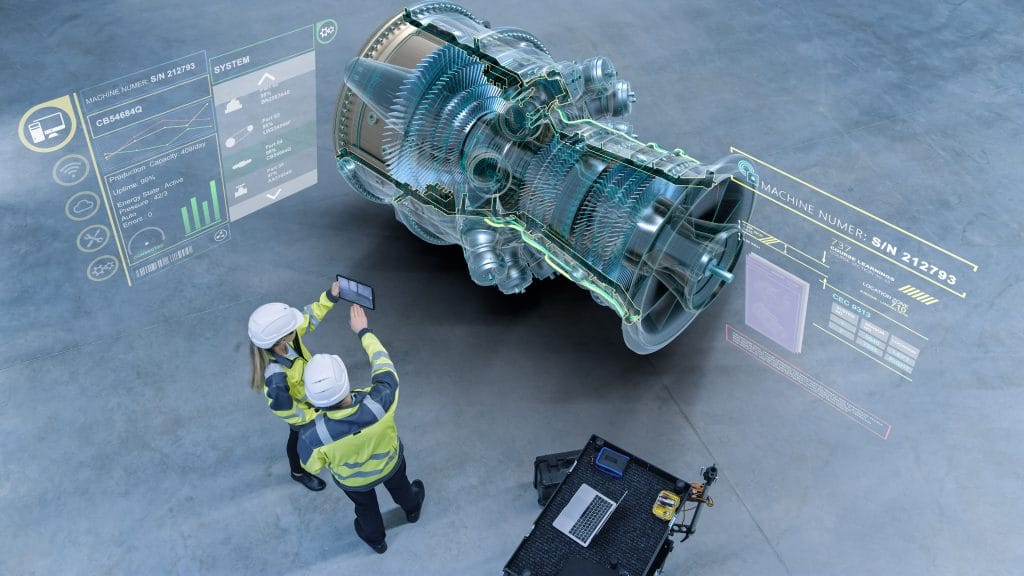

With SOLIDWORKS Simulation, engineers can run various virtual tests such as:

- Stress and strain analysis

- Thermal and fluid flow testing

- Motion and drop test simulations

How Does Virtual Prototyping Work?

A typical virtual prototyping workflow involves several key steps:

3D CAD Design

Simulation Setup

Run the Simulation

Analyze Results

Refine Design

Since SOLIDWORKS Simulation is fully integrated into the SOLIDWORKS CAD environment, this loop is fast, efficient, and free from file export/import errors.

Why Use Virtual Prototyping?

Here’s what virtual prototyping means in business terms:

- Fewer physical prototypes = Lower costs

Material and machining costs drop drastically when you test virtually first. - Faster product development

You solve problems early—before they delay production or launch. - Better products, less risk

Catch flaws that might lead to recalls, warranty issues, or customer complaints. - More room to innovate

Want to test three different versions of your idea? Now it costs zero extra in materials.

Why Choose SOLIDWORKS Simulation for Virtual Prototyping?

Many tools offer virtual testing, but SOLIDWORKS Simulation stands out for its user-friendliness and seamless CAD integration.

Key Features:

Stress and vibration testing

Drop test simulation (great for packaging and consumer goods)

Heat and airflow analysis

All inside the familiar SOLIDWORKS design environment

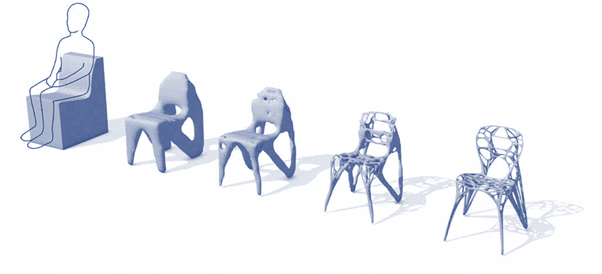

Furniture Design with Virtual Prototyping

A mid-sized furniture manufacturer needed to design a new wooden chair that could support various user weights without cracking.

Instead of building multiple physical prototypes, they used SOLIDWORKS Simulation to:

Simulate different load conditions on the chair

Identify stress points and optimize geometry

Minimize material usage while ensuring safety

Finalize the design with confidence before production

Conclusion

Virtual prototyping with SOLIDWORKS Simulation empowers engineers to move from idea to reality faster, with fewer risks and lower costs. By integrating virtual testing directly into your design workflow, you can validate ideas, refine performance, and deliver products that meet both customer needs and business goals.

Whether you’re building electronics, machinery, or furniture. Virtual prototyping is the future of smart product design.