SOLIDWORKS Flow Simulation: A First Look

When it comes to developing high-performing products, engineers can’t afford late-stage surprises. A design that looks perfect on screen may fail under real-world conditions—leading to costly delays, redesigns, and missed opportunities.

That’s where SOLIDWORKS Flow Simulation comes in. Built directly into the SOLIDWORKS environment, Flow Simulation allows you to test, predict, and optimize how your designs will behave under conditions such as fluid flow, heat transfer, and aerodynamics—all without leaving your familiar design workspace.

Source: SOLIDWORKS Blog

Integrated Simulation Inside SOLIDWORKS

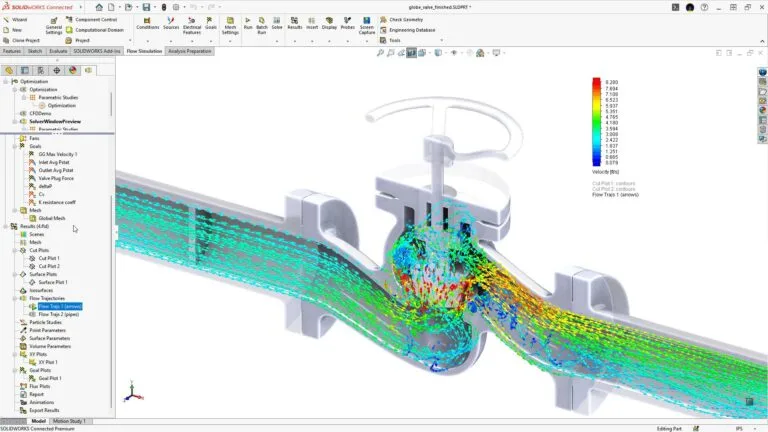

Unlike standalone CFD (Computational Fluid Dynamics) tools, Flow Simulation is seamlessly embedded within SOLIDWORKS. This means you can perform simulations alongside your design work, eliminating the need to switch between separate platforms.

Design and analyze in one place – no extra software required.

Run tests early in the design process to avoid late-stage issues.

Iterate faster by quickly comparing multiple design variations.

Source: SOLIDWORKS Blog

Key Features of SOLIDWORKS Flow Simulation

Guided Setup Wizard

Even complex simulations start easily with a step-by-step wizard. Define fluids, materials, and boundary conditions quickly and accurately—making it accessible even for users new to CFD.

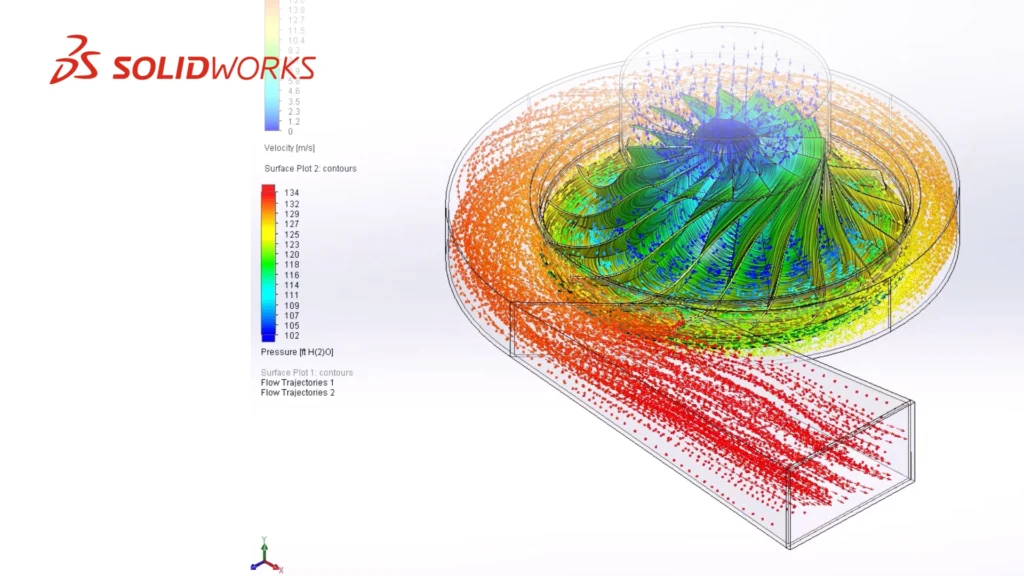

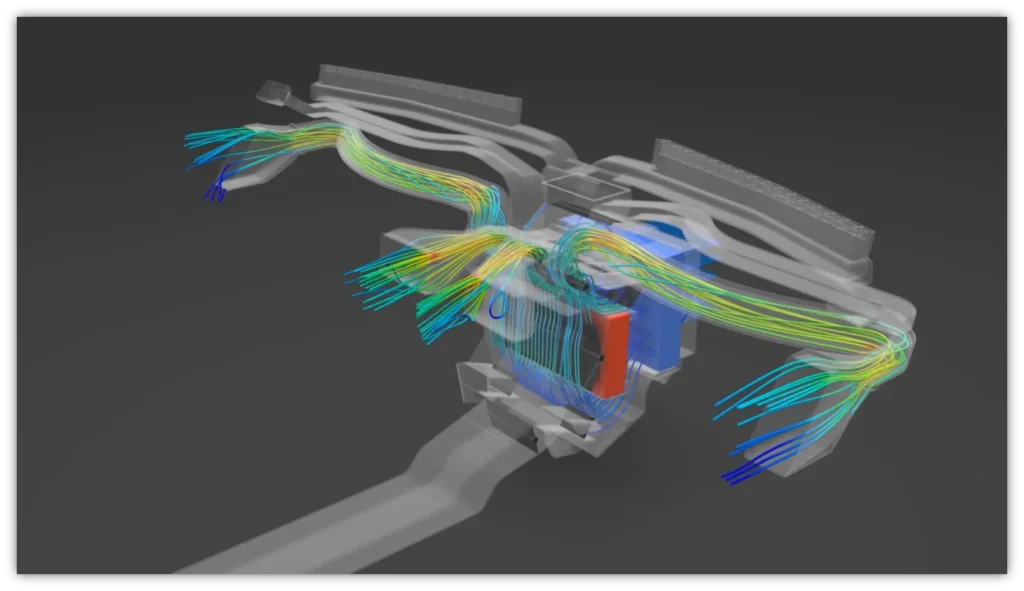

Powerful Visualization

Visual feedback is critical for understanding performance. Flow Simulation uses GPU rendering to provide clear insights into airflow, turbulence, heat transfer, and pressure distribution across your design.

Interactive Analysis Tools

Dynamic tools help engineers explore a wide range of scenarios:

Trace fluid paths to identify hot spots or bottlenecks.

Detect pressure losses that could hurt performance.

Visualize wake regions to improve aerodynamics.

Parametric & Design Studies

Easily test multiple design variations and operating conditions. From transient flow to rotating machinery, Flow Simulation helps predict how a product will behave before a physical prototype is ever made.

Built-In Libraries

Save time with preloaded libraries for fans, heat sinks, PCBs, and fluids. These resources allow you to model realistic conditions quickly while improving accuracy.

Source: SOLIDWORKS Blog

Applications Across Industries

The versatility of Flow Simulation makes it valuable across different engineering sectors:

Electronics: Ensure reliable thermal performance by simulating heat transfer in PCBs, enclosures, and cooling systems.

HVAC: Optimize ducting, heat exchangers, and airflow designs for maximum efficiency.

Aerospace & Automotive: Evaluate lift, drag, and wake regions to improve aerodynamic stability and fuel efficiency.

Industrial Equipment: Analyze pumps, valves, and impellers to minimize cavitation, ensure sealing, and enhance durability.

Why Engineers Choose Flow Simulation

At its core, SOLIDWORKS Flow Simulation is about building confidence in your designs. By running accurate simulations early, engineers can:

Reduce costly trial-and-error iterations.

Shorten prototyping cycles.

Ensure compliance with performance and safety standards.

Deliver reliable products faster to market.

Looking Ahead

As industries move towards smarter, more sustainable products, simulation is becoming an essential part of engineering. With SOLIDWORKS Flow Simulation, teams can design with clarity, test with precision, and make decisions based on data rather than guesswork. It’s more than just an analysis tool—it’s a way to innovate with confidence.

Want to explore SOLIDWORKS Flow Simulation in action? Contact us today and see how simulation can transform your design process.