Overview

The Marco Company, founded in 1984 in Fort Worth, is one of Texas’s oldest lock markers with a time-honored brand. Marco’s evolution from a small company with a limited product range to a global entity serving a broad spectrum of retailers highlights their ability to adapt and grow within the merchandising solutions industry. The one-stop shop for installations, millwork, displays, and case refurbishment, Marco has grown in reputation.

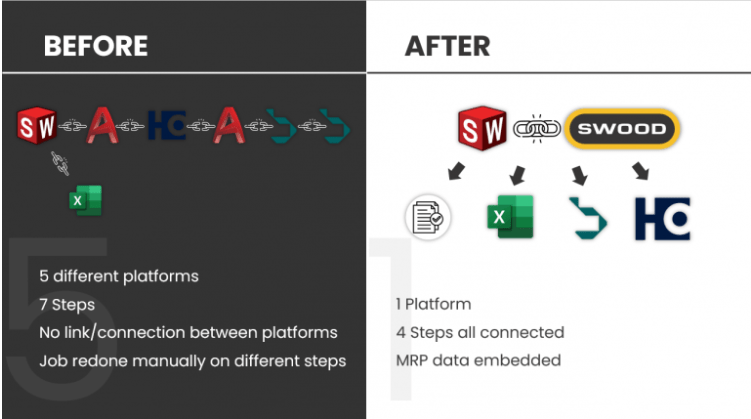

Challenges: Moving from the traditional way of working style

The Marco Company offers a vast range of services and production. However, the manual translation and rekeying of data had been complicating the workflow. On top of the challenges of meeting production demands on time, there were also difficulties in keeping up with drawings and programs.

Solution: SWOOD

- Integration of feature recognition – Minimizes the need for manual programming by streamlining the design-to-production process

- Machining libraries – Optimise programming speed and ensure consistency

- Embedded toolpath/CAM information in the SOLIDWORKS file – Facilitates transferring data from design to production, minimising errors and manual rekeying, and 3D designs can be directly sent to the CNC machines.

- High fidelity from screen to machine – The native bpp files generated by SWOOD guarantee that the program can be loaded by the operator without modification but produce precise and safe components.

- Nesting feature – Increases efficiency in getting the correct documentation as it is easier and faster, now that all the need for rekeying of dimensions and data has been eliminated, thus preventing mistakes or translation issues.

“With SWOOD we have very high fidelity from screen to machine, what you see is what you get. Now we do a virtual review process where everyone signs off on the model in SOLIDWORKS and we quickly and accurately deliver production paperwork and programs to manufacturing. The thing about SWOOD is the speed and flexibility of the tools and that I can trust it will deliver accurate paperwork and machine code to manufacturing. It is designed for our industry and has all the features you need in a very simple, visual, drag-and-drop interface.”

Greg Ohlin, Director of Engineering

Looking for a similar solution? Explore the capabilities of SWOOD here or contact us to schedule a free appointment!