Detail drawings are where a design becomes buildable. While plans, elevations, and sections communicate the overall intent, a detail drawing focuses on a specific area and explains exactly how it should be assembled, connected, or installed.

If you have ever seen a contractor ask, “How does this join?” or “What is the fixing method here?”, that is the gap detail drawings are meant to solve.

What is a detail drawing?

A detail drawing is a close-up technical drawing that shows a component or junction at a larger scale. It captures information that is usually too small to communicate clearly in general drawings.

A detail drawing may include:

precise dimensions and notes

material callouts

fixing methods and connection details

tolerances or clearances, when relevant

section views to show internal relationships

The purpose is to remove uncertainty and make the build process easier to follow.

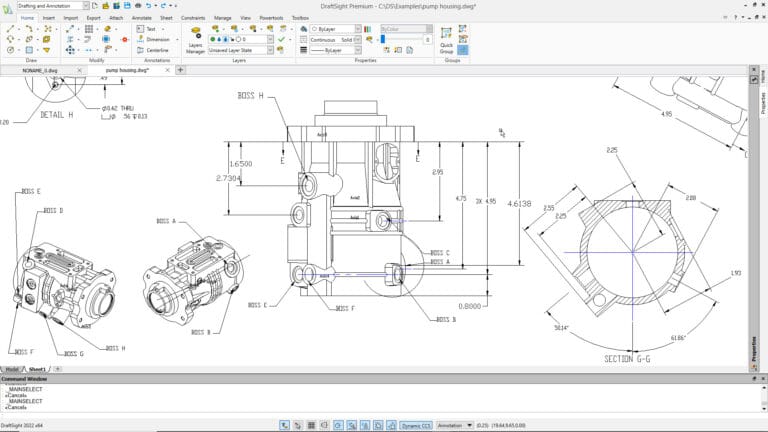

Detail drawing example

Think of a detail drawing like zooming in on a critical part of the design.

A building plan might show the locations of walls and windows, but a detail drawing can show how the window frame connects to the wall, how waterproofing is applied, and where the fasteners are placed.

In mechanical or product design, a detail drawing might focus on a housing, bracket, or interface between parts, including dimensions and features that must align correctly during assembly.

Where detail drawings are used

Detail drawings are common in both construction and engineering because they prevent guessing. When teams can see exactly how elements should come together, there are fewer site questions and fewer reworks.

Detail drawings are usually produced once the overall design direction is set and the project is moving into coordination and documentation.

Construction detail drawings

Construction detail drawings support the practical “how to build it” part of a project. They often zoom in on interior or exterior building elements such as:

wall build-ups and insulation layers

door and window installation details

floor and roof junctions

waterproofing, flashing, and edge conditions

cabinetry, finishes, and joinery details

A good construction detail drawing is easy to read and hard to misinterpret. Clear notes, correct scale, and clean dimensioning matter because site teams rely on these drawings to execute work accurately.

Detail drawings are usually produced once the overall design direction is set and the project is moving into coordination and documentation.

Engineering detail drawings

Engineering detail drawings are typically more technical and may include functional requirements that support safety and performance. They often show:

component geometry and critical dimensions

specifications for materials and finishes

tolerances and fit where required

connection methods for structural and mechanical elements

For example, a steel member detail might include sizes and connection information needed to fabricate and install it correctly.

Digital tools that help detail drawings

If you create detail drawings often, DraftSight can help you work faster and keep drawings consistent:

layers for better organization

blocks and templates for reuse

tools for clean linework and annotation

Tips for accuracy and clarity in detail drawings

You have a few options based on what you need to do.

1) Use consistent labeling and notation

Consistency is one of the fastest ways to improve readability. Use the same naming format for parts, notes, and callouts across all drawings. Keep text styles and symbols aligned with your office standards.

A practical approach:

keep notes short and direct

avoid vague language like “fix as required”

label critical components clearly and consistently

2) Choose the right scale for the information

General drawings often use smaller scales, but detail drawings need a larger scale so connections and materials are readable.

Examples of common detail scales include 1:10 or 1:5, depending on what you need to communicate. The goal is simple: the detail must be readable at the intended print size.

3) Dimension only what the builder or fabricator needs

More dimensions do not always improve clarity. Too many dimensions can create clutter or cause conflicting values if revisions occur.

A better approach:

dimension critical sizes, clearances, and reference points

avoid repeating the same dimension in multiple places

ensure dimensions support how the element is built or measured onsite

4) Use layers and lineweight discipline

Layer structure helps readers separate key information quickly, especially when a detail includes multiple systems.

A good layer strategy:

separate structure, finishes, and services where possible

keep hidden or secondary elements lighter

make cut lines and key edges visually stronger

5) Add section views where needed

When a junction cannot be explained clearly in a single view, add a section or callout detail. Sections often communicate build-ups and internal relationships better than plan views alone.

6) Keep details tidy and easy to scan

Readability is not only about accuracy. It is also about how quickly someone can understand the detail.

Do a quick print check:

confirm text is readable at scale

verify that dimensions do not overlap

ensure hatches do not overwhelm the drawing

check that leaders and callouts point clearly to the correct items

Want a smoother workflow for CAD detail drawings?

DraftSight can support detail drawing production with tools for layers, annotation, templates, and dimensioning workflows.

Adapted from DraftSight Blog: “Detail Drawing: Techniques for Accuracy and Clarity”.