The woodworking market is evolving. Are your tools evolving too?

Your craftsmanship, experience, and know-how are the foundation of your business. At the same time, customer expectations are rising. Many clients now want faster delivery, more customization, and smooth execution, even when they request multiple changes.

If you are still relying heavily on manual sketches and repeated adjustments, it often leads to rework, cutting mistakes, and unnecessary material waste.

A practical solution is to adopt Computer Aided Design and Manufacturing software, also known as CAD/CAM. CAD/CAM does not replace your skills. It strengthens your workflow so you can spend more time creating and less time fixing avoidable issues.

1) Save time and reduce production errors

How often do you need to redo a plan because of one small measurement mistake? How many hours are lost correcting a piece that was cut slightly wrong?

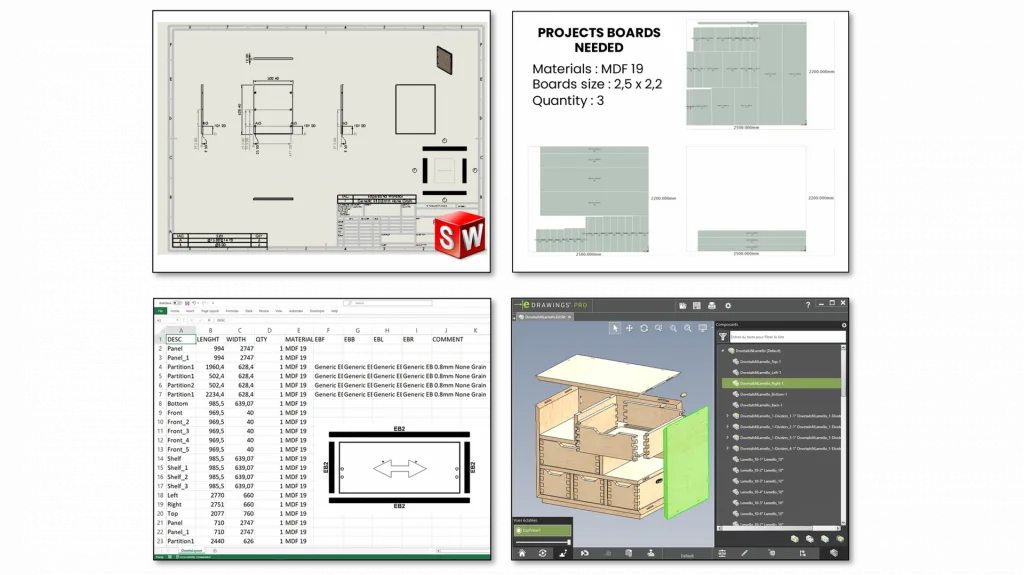

With 3D CAD software, details are calculated accurately so you can work with confidence.

You can benefit from:

precise project design from the start using reusable models and hardware libraries

early error checking before machining begins

faster updates when a dimension changes, especially with parametric design tools that update related parts automatically

Solutions like SWOOD support this kind of parametric workflow, which helps reduce manual editing across the project.

2) Expand creativity while staying technically confident

Many workshops have ideas that feel too complex or too risky to build. That hesitation can limit the types of projects you take on.

With woodworking CAD/CAM software, complex designs become easier to plan and execute:

detailed 3D parts with accurate fit and finish

project-wide updates without redrawing everything

built-in rules and constraints to help validate the design before production

This makes it easier to explore ambitious designs while keeping control over feasibility.

3) Cut costs without lowering quality

Material waste reduces profit. Mistakes that require extra boards or sheets add cost and slow down delivery.

CAD/CAM helps you control costs because optimization is part of the process:

you can visualize machining steps before production begins

nesting strategies improve sheet usage and reduce scrap

repeating similar projects becomes faster by reusing existing designs and templates

When planning improves, waste goes down and productivity goes up.

4) Give clients a premium and more confident buying experience

When clients are unsure, approvals slow down and comparison shopping increases. Clear visuals make decisions easier.

With CAD/CAM, you can:

show realistic 3D views so clients understand what they will receive

adjust the design during discussions without rebuilding everything

shorten the approval cycle and reduce back-and-forth communication

This improves trust, speeds up decisions, and supports higher value sales.

5) Streamline production and stay in control

In any workshop, poor planning creates stress. Clear production information creates stability.

With a solution like SWOOD, the workflow can be connected from design to production:

generate reports and documentation such as drawings, part lists, quantities, and cost details

extract data automatically for purchasing and planning

output CNC-ready machining files through post-processing to support machine compatibility

A structured workflow helps reduce surprises and keeps production moving smoothly.

6) Support sustainability while improving profitability

Reducing waste is good for the environment and good for the business.

With CAD/CAM, you can improve:

raw material planning

scrap reduction and fewer remakes

your sustainability message for eco-conscious customers

overall operating costs through better efficiency

Ready to take your woodworking workflow to the next level?

With the right CAD/CAM tools, woodworking businesses can reduce errors, improve efficiency, and deliver better customer experiences.

Common results include:

fewer mistakes and less rework

improved customer satisfaction

reduced waste

more projects completed in less time

If you are considering SWOOD for your workshop, we can support you with guidance, setup, and training so you can implement it smoothly. Contact us Today!

Adapted from SWOOD Blog: “6 key benefits of using design and manufacturing software (CAD/CAM) for woodworking industry”.