Introduction: The Real Cost of Downtime in Malaysia’s Manufacturing Sector

In Malaysia’s fast-paced manufacturing landscape, even a few hours of unplanned downtime can result in substantial financial losses. From palm oil refineries in Johor to electronics assembly plants in Penang and high-volume food processing facilities in Selangor, equipment reliability is a major concern.

Machine breakdowns not only halt production but also create ripple effects across logistics, delivery timelines, and customer satisfaction. As competition intensifies and demand for higher quality rises, more manufacturers are turning to engineering simulation tools—such as SOLIDWORKS Simulation—to preempt equipment failures and boost machine performance from the design phase.

Why Equipment Reliability is a Challenge for Malaysian Manufacturers

Manufacturers in Malaysia operate under a unique set of environmental and operational constraints that increase the wear and tear on machinery. Let’s break down a few common pain points:

- High humidity and heat accelerate corrosion, especially in outdoor or uncooled facilities.

- Heavy mechanical loads in sectors like palm oil milling, chemical processing, and rubber manufacturing increase the risk of structural failure.

- Trial-and-error prototyping takes time and money but doesn’t always produce optimal results.

- Long lead times for imported spare parts leave production lines idle while waiting for replacements.

- A shortage of in-house simulation skills often means relying on expensive external testing or delayed troubleshooting.

These issues have made it increasingly clear that conventional “reactive” approaches to maintenance and design are insufficient. Manufacturers need a predictive, cost-effective solution to design robust systems and catch failures before they happen.

Business Advantages of Simulation-Driven Design

Investing in simulation software like SOLIDWORKS Simulation brings measurable ROI through both direct and indirect benefits:

Reduce Downtime, Increase Machine Uptime

Virtual testing helps eliminate design flaws early, minimizing unexpected equipment failures during operation.

Faster Time-to-Market

Simulation reduces the need for physical prototypes, speeding up product development cycles.

Lower Maintenance and Warranty Costs

Machines designed with accurate stress and fatigue data are less likely to break down, reducing after-sales support burdens.

Boost Competitive Edge

Being able to show clients your machine was verified using Finite Element Analysis (FEA) or CFD simulations can increase confidence and win contracts—especially in regulated industries like food, energy, and aerospace.

Cost-Efficient Iteration

Instead of spending thousands on physical redesigns, simulations allow for rapid testing of new ideas in a matter of hours.

Making Simulation More Accessible for Malaysian SMEs

Gone are the days when only multinational corporations could afford simulation software. With cloud-based options and bundled packages like SOLIDWORKS Simulation Standard, Malaysian SMEs can now enjoy:

- Lower upfront investment

- Scalable licensing options

- Integration with existing CAD workflows

- Local training and support from certified resellers

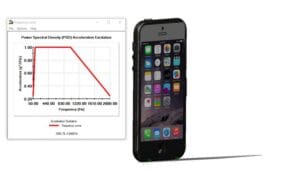

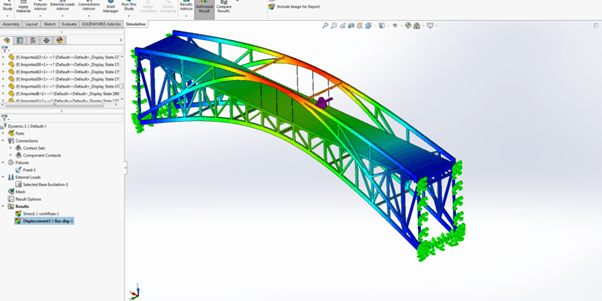

Simulation Tools: A Smarter Way to Design and Test Machinery

SOLIDWORKS Simulation and similar software offer manufacturers the ability to test, validate, and optimize designs in a virtual environment—before any physical prototype is produced. These tools replicate real-world conditions, helping engineers improve reliability and performance at the source.

Key Simulation Capabilities Manufacturers Are Using:

Stress Analysis with FEA (Finite Element Analysis)

Simulates how forces like pressure, vibration, and torque affect different machine components. This allows engineers to:

• Identify weak points in frames, gears, or shafts

• Prevent bending, deformation, or cracking under load

• Optimize material usage without compromising strength

Fatigue Testing

Predicts the life span of components under repeated loading and unloading cycles. With fatigue analysis in SolidWorks, users can:

• Prevent sudden failures from repeated stress

• Plan preventive maintenance schedules more accurately

• Extend the life of high-cycle parts like bearings, blades, or joints

Thermal and Heat Transfer Simulation

Essential for industries like food processing, plastics, and electronics. This analysis:

• Identifies hotspots in enclosed environments

• Improves cooling system designs

• Helps simulate airflow and heat dissipation using SolidWorks Flow Simulation

Computational Fluid Dynamics (CFD)

Fluid flow simulation is especially useful for pump systems, piping networks, and cooling channels. With SolidWorks CFD, engineers can:

• Simulate liquid and gas flow in complex systems

• Optimize HVAC or piping design

• Detect flow restrictions or turbulence zones early

Final Thoughts: From Reactive to Predictive Engineering

Malaysia’s manufacturing sector is moving quickly toward Industry 4.0. Simulation isn’t just about analysis—it’s about building smarter machines that run longer, fail less, and adapt faster to new demands. With the right tools, like SOLIDWORKS Simulation, and the right mindset, even traditional manufacturers can evolve their product development strategy—transforming reliability from a guessing game into a precise, data-driven process.