INTRODUCTION

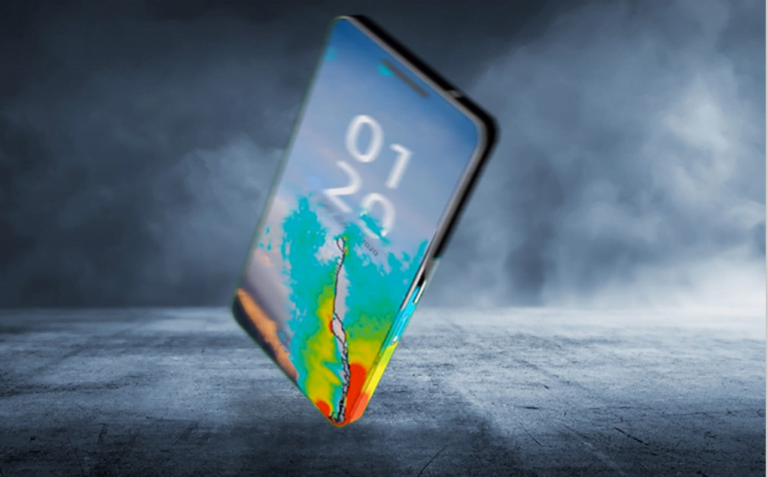

In the ever-evolving world of product design and engineering, ensuring that products can withstand real-world conditions is crucial.

One of the standout capabilities of SOLIDWORKS Simulation is the Drop Test feature, which helps engineers predict how their designs will perform when subjected to impacts. This simulation tool is not just a luxury but a necessity for developing robust products that can handle the rigors of everyday use.

PRODUCT STUDY AS ONE OF THE PILLARS IN DESIGN INTENT

The primary goal of any design process is to create a product that not only meets aesthetic and functional requirements but also endures real-world stresses.

Product studies, including drop tests, are essential pillars in achieving this design intent. By incorporating simulations that model how a product behaves under impact conditions, engineers can gain valuable insights into potential weaknesses and areas for improvement before physical prototypes are made. This proactive approach can save time, reduce material waste, and enhance overall product reliability.

CASE STUDY: WILSON CASE

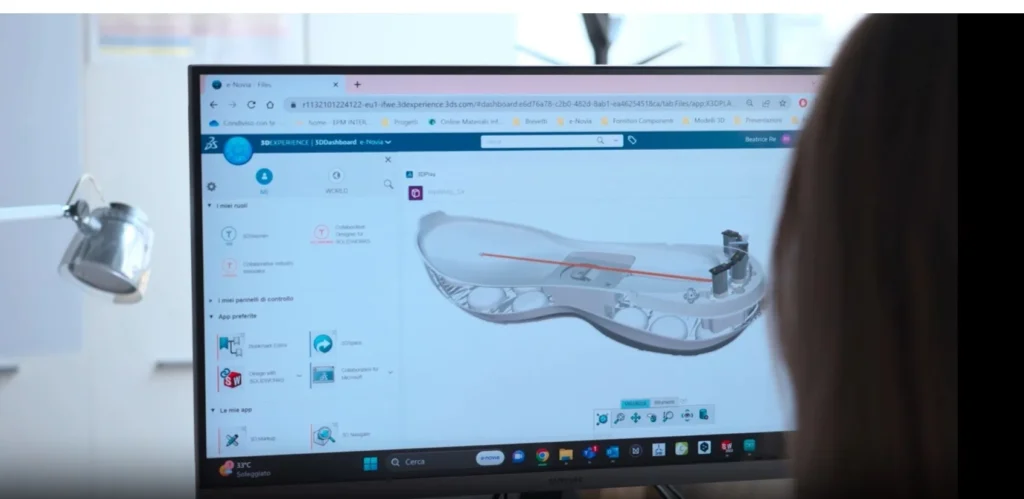

To illustrate the practical benefits of SOLIDWORKS Simulation Drop Test, let’s delve into a real-world example: Wilson Case. Wilson, a renowned company specializing in protective cases, utilized SOLIDWORKS Simulation to enhance their product design process.

- To provide accurate insights to customers’ inquiries regarding product load and performance capabilities without the expense of physical prototypes.

- To save time and cost, while improving product performance, hence creating a revenue-generating validation service.

Solution:

- Implemented SOLIDWORKS Simulation Drop Test to analyze how their protective cases perform under impact, such as in the case of the product dropping out of the back of a truck.

Results:

- Increased Client Satisfaction: By predicting and mitigating potential failures, Wilson Case improved the reliability of their products.

- Time and Material Savings: Reduced the need for costly physical prototypes and minimized material waste through early-stage simulations.

- Enhanced Design Efficiency: Streamlined the design process by identifying weaknesses early, allowing for more effective iterations.

You can read more about Wilson Case’s success story here.

WHY SOLIDWORKS SIMULATION DROP TEST

To illustrate the practical benefits of SOLIDWORKS Simulation Drop Test feature offers several advantages for engineers and designers who aim to optimize their 3D designs by balancing various aspects such as form, material, durability, and usability:

• Early Weak Point Detection: Offers accurate impact analysis and identifies failure points early, refining the design to withstand real-world conditions and eliminating repeated physical tests.

• Time and Cost Efficiency: Reduces the reliance on costly physical prototypes by allowing engineers to test and iterate designs digitally, saving both time and resources.

• Integration with Design Models: Seamlessly integrates with existing SOLIDWORKS models, making it easy to incorporate drop test simulations into your workflow without additional complexity.

• Enhanced Product Reliability: Ensures that your products meet rigorous durability standards, leading to higher customer satisfaction and fewer rejects.

Discover more about SOLIDWORKS Simulation here.

JOIN OUR SOLIDWORKS SIMULATION DROP TEST HOTD

Are you interested in learning how to leverage the SOLIDWORKS Simulation Drop Test to enhance your product design process? We invite you to join our upcoming Hands-On Test-Drive (HOTD) Workshop, where we’ll dive deep into the capabilities of this powerful tool!

Event Details:

📆 Date: September 17, 2024 (Tuesday)

🕑 Time: 2-5 PM

📍 Venue: CADVision Systems Singapore

Be sure to secure your spot here before they run out!

CONCLUSION

Incorporating SOLIDWORKS Simulation Drop Test into your design workflow is more than just a technical upgrade; it’s a strategic move towards more resilient, reliable, and cost-effective products.

It is important for engineers and industrial designers to understand and utilize this tool to make a significant difference in their product development journey.